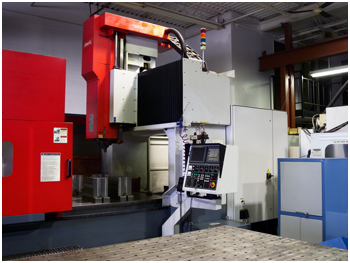

Shop Capabilities

The latest in CNC technology

- Our machining centers give us the flexibility to complete any machining task to the highest accuracy.

- All of our CNC utilize the latest in high speed machining technology for fast and accurate milling in any application.

- Large size (120” x 60” x 40”) bridge type CNC machine allows for die-set machining and other large programs.

- Probing and laser measuring for accurate and fast setup

Advanced machining

- High speed machining as part of a broad machining strategy.

- Hard milling after heat treatment for quality and accuracy of die components.

- 5-axis machining center for reduced lead times on complex assemblies. (cam stations, deep-draw dies, etc.)

- Industry leading CAM software for accurate, fast and reliable machining. (WorkNC, Mastercam)

- Highly trained operators and programmers skilled in all parts of die building.

Manufacturing solutions

- Implementation of a water-jet cutting machine speeds up the developing and die building process.

- The roll-out tank (100” x 50”) allows for fast setup.

- A high pressure intensifier pump for cutting of up to 4” thick steel plate.

Complete EDM

- Next generation EDM technology facilitates fast cutting of die steels.

|

|